Going In Circles

- Level

- Intermediate

- Session

- 3 hours

- Description

- Going in Circles is fun if you are on a merry go round, a dog or making a ring, right? This modern ring can be skewed to your liking, whether you prefer clean sleek lines or a more organic feel, I will walk you through the process and show you how it is done.

Tools

-

Bench Block

Steel or Anodized aluminum - Used as a hammering surface for metal stamping or working with metal. -

Bench Pin

There are a variety of bench pins available on the market, any will do. However, you will need to bring a 4” or larger C-clamp. As the C-clamp provided with a bench pin does not fit most tables at the shows. -

Carbon Ring Mandrel

Used for soldering elementst to rings. Solder will not adhere to the carbon rod and heat sink is at a minimum compared to a ceramic rod. -

Chasing Hammer

Used for chasing/moving metal. In my classes chasing hammers are used to create hammer marks on metal and riveting. Instructor will provide for every class needed. -

Cut Lube

Used to lubricate saw blades and drill bits for ease of cutting. -

Fine Tweezers

Used for moving small parts. Classes requiring fine tweezers will not work with fire tweezers. These are a cheap investment. Please be bring some. Optional for most classes. -

Flex shaft

Rotary tool used for polishing, drilling, finishing, etc. Flex shafts are available for purchase new and gently used at the class. Pleased contact the instructor if are interested in purchasing one at the class as quantities are limited. -

Hand Tools

Basic hand tools – Any quality is appropriate for my classes. These do not need to be high end or expense.

- Round nose - Typically it is preferred that the round nose be a fine tip. Especially for classes with detailed wire work.

- Chain/needle nose – Tapered jaws for general metal and wire work. Non-serrated are requested for all of my classes. Typically requested for classes to be used for opening and closing jump rings; in which case, 2 pairs are requested or a combination of chain nose and flat nose is suitable.

- Flat nose – Similar to chain nose but the jaws are not tapered. Non-serrated are requested for all of my classes.

- Round nose - Typically it is preferred that the round nose be a fine tip. Especially for classes with detailed wire work.

-

Helping Hand/Third Hand

Used to hold small parts in place while soldering. Instructor will provide to share for every class needed. -

Jeweler’s Saw

Used for cutting sheet metal and metal tubes. Instructor will provide for every class needed. -

Magnifier or Optivisor

– For almost all classes this is listed as an “As Needed” tool. If you have sight challenges it is recommended that you are properly prepared. For advance stone setting classes this is required! If you decide to use reading glasses consider better than 2.5x.

-

Muslin buffing wheels

Used with a flex shaft or Dremel to polish metal. -

Needle File Set

Used for filing smaller pieces of metal and tight places. When required, either diamond coated or fine tooth is preferred. Some students may prefer to use smaller files as opposed to the student files for their projects. -

Ott Light or Task Lamp

This is optional item that is listed for every class. It is up to you to determine whether or not you will need to have one depending on your vision. -

Rawhide/Leather Mallet

Shape and flatten metal without marring it. #2 mallet is a standard size. Instructor will provide for every class needed. A yellow nylon mallet may be used in its place, however a rubber one may not. -

Ring Mandrel, Steel

Used for shaping and forming metal into rings. A plastic one will not work in its place. Instructor will provide to share (1 for every 2 people) for every class needed. -

Ring Sizer

Optional, used to measure your ring size. Several sets will be provided to share in class. -

Metal Ruler

6" metal ruler is preferred unless otherwise noted. A larger one will also work, however, it may be a little cumbersome. -

Setting Bunisher

Concaved punches used to set stones.

-

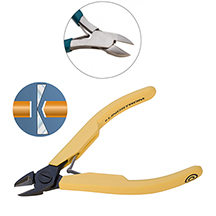

Side Cutters

Also known as wire cutters or snippers. For many of my classes I prefer Ultra Flush side cutters because it eases the workload. Ultra flush is the most flush you can buy as opposed to just flush cutters. If you don't own a pair of Ultra Flush cutters, you may want to invest in a good pair either Lindstrom or Swanstrom. There is usually not a different in price between ultra and just flush cutters so why not just buy the best? The image shows just a side cutter (top) and ultra flush (bottom).